The INFINITY AML Automatic Solid Chocolate Moulding Line is designed to produce any solid chocolate moulded item using standard 275 x 175mm or 275 x 135mm polycarbonate chocolate moulds. It can deposit up to 100g per second with a maximum throughput rate of 600 moulds per hour.

£10,200.00

The INFINITY AML-2 is designed to work with either an INFINITY MX or AX tempering machine. It consists of five stations:

Moulds can then either run directly into a cooling tunnel or can be manually removed and placed in a cooling rack.

Do You Make Flavoured Chocolate Bars?

If you regularly make chocolate bars in many different flavours – whether it is different origin chocolates, flavoured chocolates or even just dark, milk and white – an INFINITY AML teamed with 3, 4 or even more INFINITY MX/AX tempering machines could be a highly versatile and surprisingly cost-effective solution for your business needs. As the AX/MX machines can each be “wheeled in” and “wheeled out” as you need, you can keep your moulding line going all day producing at the rate of 150kgs/hr, or until you run out of moulds!

“Many thanks for the delivery and set-up of the machine. I am pleased to say that our chocolatiers are delighted with its performance and reliability and consequently production has increased dramatically”….. Steve from Gwynedd Confectioners, about the INFINITY LX with Automatic Mould Feeder

“Keychoc equipment is second to none. Most of our mission critical equipment is made by them none of it fails and if there is ever any maintenance required Steve, Mark and the team are always on the end of the phone for advice. We have Keychoc machinery which is over 10 years old and it still performs like new. I have no hesitation in recommending them to anybody regardless of business size.”

The INFINITY AML-2 is designed to work with either an INFINITY MX or AX tempering machine. It consists of five stations:

Moulds can then either run directly into a cooling tunnel or can be manually removed and placed in a cooling rack.

Do You Make Flavoured Chocolate Bars?

If you regularly make chocolate bars in many different flavours – whether it is different origin chocolates, flavoured chocolates or even just dark, milk and white – an INFINITY AML teamed with 3, 4 or even more INFINITY MX/AX tempering machines could be a highly versatile and surprisingly cost-effective solution for your business needs. As the AX/MX machines can each be “wheeled in” and “wheeled out” as you need, you can keep your moulding line going all day producing at the rate of 150kgs/hr, or until you run out of moulds!

“Many thanks for the delivery and set-up of the machine. I am pleased to say that our chocolatiers are delighted with its performance and reliability and consequently production has increased dramatically”….. Steve from Gwynedd Confectioners, about the INFINITY LX with Automatic Mould Feeder

Keychoc is a supplier

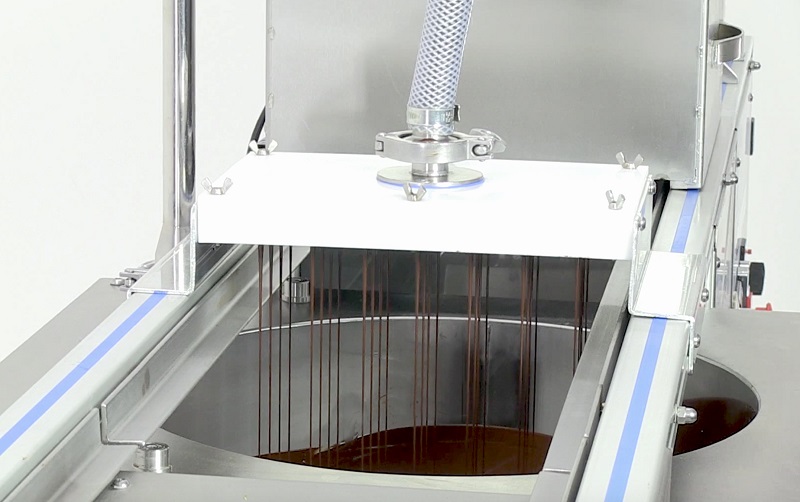

of vibrating tables and

guitar cutters to the

Barry Callebaut UK Academy